Helping flexible solar panels last longer

Researchers at Holst Centre and DuPont Teijin Films have created a high-performance yet cost-effective roll-to-roll barrier solution designed specifically for flexible photovoltaic (PV) cells. This production-ready solution combines Holst Centre’s advanced barrier technology with DuPont Teijin Films’ Peelable Clean Surface film.

It could help extend the yield and working lifetime of organic, perovskite and CIGS PV cells, opening the door to cheaper, environmentally-friendly solar generation in more situations.

Energy that helps and withstands the environment

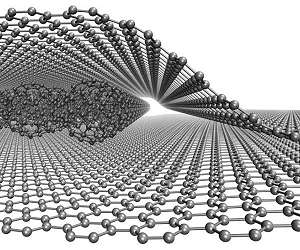

Flexible PV cells offer the promise to embed clean energy generation into construction materials, vehicles and all kinds of everyday objects. They also bring the possibility of using high-volume roll-to-roll (R2R) production processes that could significantly cut manufacturing costs. However, the cells are susceptible to moisture and atmospheric oxygen, and thus require an impermeable barrier to protect the sensitive thin films.

Holst Centre has significant experience in developing moisture barrier solutions, including a very high performing flexible barrier developed for Organic Light Emitting Diode displays. While the moisture resistance for PV cells does not need to meet these challenging standards, it must still perform at a level far above that of required for sensors, electrophoretic displays, RFIDs, LCDs etc.

Delivering high-performance protection

One of the key elements in creating a good barrier film is ensuring that the inorganic barrier layer is deposited on a very clean surface, keeping the number of particle-induced defects in the barrier layer as low as possible.

Typically, this is done by adding an organic coating to planarize the substrate surface before applying the barrier layer. But this extra step adds to the overall production cost of the barrier film and the organic materials for planarization still have limited commercial availability.

The Peelable Clean Surface substrate, MelinexPCS, from DuPont Teijin Films (DTF) delivers a clean substrate surface without the need for a planarization step or other cleaning process, saving both time and costs for producing barrier film for flexible PV cells. The clean substrate ensures an optimal deposition of the barrier layer, requiring just a single inorganic barrier layer to protect the PV cells.

Ready for commercial production

The solution has been optimized over the last two and half years to bring the performance of the substrate foil and the barrier layer to a production-ready level. Working closely together, Holst Centre and DTF, have developed a solution that is already capable of fabricating the barrier film at volumes in the range of thousands of square meters on the Lyteus pilot line.

The developed barrier solutions has been successfully tested by Solliance for encapsulation of CIGS (CuInGaSe2) modules. After 1000hr accelerated life time testing (85 C-85% Relative Humidity) the performance was still above 95% of the starting performance.

“The experience gained working with the Lyteus pilot line, together with input from the Holst Centre team, allowed us to improve the performance of our Peelable Clean Surface film for roll-to-roll production of moisture barrier film for flexible photovoltaics,” said Valentijn von Morgen, Senior Process Engineer at DTF.

“We intend to make this unique film commercially available for use in the mass production of barrier films and other flexible electronic products, and continue with development programmes to modify the properties of Melinex PCS to tailor the film for different barrier applications and environments.”

“Our goal is not just to develop innovative technologies, but to develop solutions tailored to specific markets. As such, the single layer barrier on the Peelable Clean Surface film we have developed for encapsulation of flexible PV cells has been tailored to meet the cost/performance needs of the market”, said Pavel Kudlacek, Senior Researcher and Project Manager at Holst Centre. “The complete solution is now ready to be scaled for mass production by the industry.”

Related Links

Holst Centre

All About Solar Energy at SolarDaily.com

|

We need your help. The SpaceDaily news network continues to grow but revenues have never been harder to maintain. With the rise of Ad Blockers, and Facebook – our traditional revenue sources via quality network advertising continues to decline. And unlike so many other news sites, we don’t have a paywall – with those annoying usernames and passwords. Our news coverage takes time and effort to publish 365 days a year. If you find our news sites informative and useful then please consider becoming a regular supporter or for now make a one off contribution. |

||

|

SpaceDaily Contributor $5 Billed Once credit card or paypal |

SpaceDaily Monthly Supporter $5 Billed Monthly paypal only |

|

![]()

Fullerenes bridge conductive gap in organic…